ICECON thermal Insulation Boxes is helpful for the vaccine transportation

2021-01-01 19:22The global cumulative confirmed cases of COVID-19 officially entered the "60 million+" stage starting on November 26, 2020, and the number of new confirmed cases reached a new high of over 740,000 on November 28, 2020. The global situation of the COVID-19 pandemic remains severe, and the development and use progress of COVID-19 vaccines have always been a topic of concern for people. It is understood that due to the special nature of vaccine products, in addition to the vaccines themselves needing to have sufficient safety and efficacy, the entire process from production to storage and transportation requires a sterile environment, and the storage and distribution process requires a full cold chain, which places high demands on the equipment for storing and transporting vaccines. Throughout the process, once the vaccine deviates from the designated temperature range, it is prone to lose effectiveness and poses serious safety risks. ICECON has been exploring cold chain storage and transportation for vaccines.

Choose ICECON for low-temperature vaccine transport boxes:

1. The box is resistant to low temperatures: The box is made of LLDPE special modified material, which can withstand temperatures below -78°C without becoming brittle after long-term freezing. It can ensure the safety of the vaccines inside the box and is suitable for the requirements of the current -70°C storage and transportation environment for certain vaccines in the United States.

2. Integrated molding is not easily damaged: The product has almost no internal stress during the rotational molding process, making it resistant to deformation, durable, and impact-resistant, which can better protect the safety of the vaccines inside the box. The seamless integrated molding product has uniform wall thickness and no seams. The box has good sealing performance, which can effectively isolate the internal and external environments and keep the internal environment free from contamination.

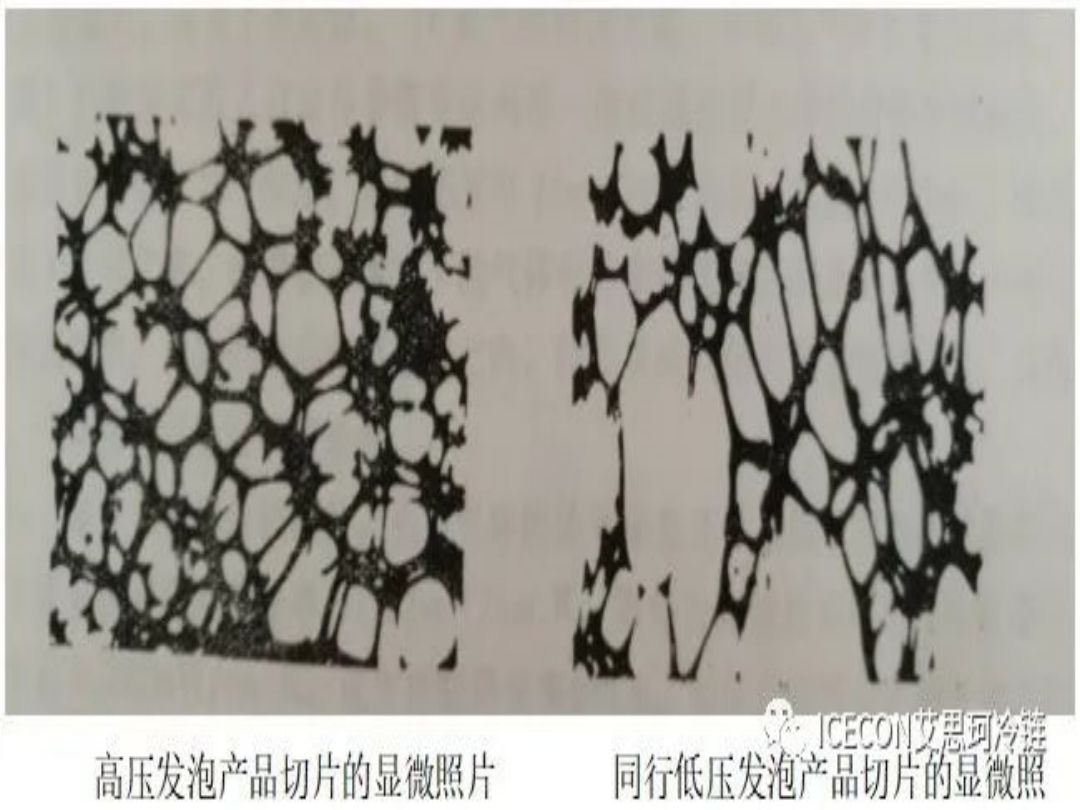

3. High-pressure polyurethane foaming technology: Our company's research consultant has won the Aerospace Department's Science and Technology Progress Award in the field of polyurethane foam research. We have independently developed and improved PU insulation materials with a thermal conductivity coefficient of ≤22mw/m·k (the thermal conductivity coefficient of domestic counterparts is about 30mw/m·k ), greatly improving the insulation duration and temperature control performance of the box.

Dry ice is the refrigerant with good low-temperature vaccine storage and trans

portation effects.

Dry ice is solid carbon dioxide, which condenses carbon dioxide into a colorless liquid and then rapidly solidifies under low pressure. It has a temperature of minus 78.5°C and directly sublimates from solid to gas when dissolved, without producing any water or liquid. It can be used for low-temperature freezing medical purposes, as well as transportation of plasma, special drugs, electronic low-temperature materials, precision components, etc.

Advantages of using dry ice for vaccine transportation:

1. Rapid cooling through physical contact: By burying the vaccines in dry ice, a temperature environment below -70°C can be achieved quickly. For vaccines that need to be stored below -70°C, dry ice is an effective refrigerant for transportation and storage.

2. No temperature loss due to power outage during transportation: By adding sufficient dry ice, the temperature for vaccine storage and transportation can be maintained at a constant level. We have conducted experiments to simulate vaccine transportation in our boxes, and detailed test data can be obtained by contacting our company.

3. No need for special vehicles: Various types of vehicles can be used for transportation, effectively solving the problem of requiring specialized vehicles for vaccine distribution.

ICECON offers various models of vaccine dry ice storage boxes.

ICECON is a company dedicated to the development of rotational molding insulation boxes, including food insulation boxes, cold chain transportation boxes, dry ice insulation boxes, and other products, all of which have passed ISO9001 certification. With a 32,000 square meter factory, ICECON integrates research and development, design, and manufacturing. With advanced equipment, strong technical strength, rich industry experience, and good management, we continuously innovate and strive to provide customers with high-quality products, making us a pioneer brand in the industry.